Choosing Direct Thermal Labels

Make the right descision choosing between Direct Thermal or Thermal Transfer

- Requires no ribbon, ink or toner

- Prints in black and white only

- Low Maintenance

- Can fade over time

- Printers are less expensive

- Not recommended for high-contact use

Direct thermal labels are excellent for common barcode applications such as mailing and shipping labels, receipt labels, distribution inhouse, nametag labels, ecommerce shipments

Let’s start with the printers. First of all, most modern printers can print both thermal transfer and direct thermal allowing you to choose your preferred method or substitute one for the other if an application requires it or one of your supplies runs out. The one advantage that direct thermal labels may have here is that DT only printers tend to be less expensive as they do not require the ribbons spool and winding mechanism.

Next up, direct thermal can me more advantageous than thermal transfer in the area of productivity time. This can be especially critical on high speed automated shipping lines with conveyors. Even an experienced printer operator will require several minutes to change a roll of ribbons, causing a production line to be down for up to 15 minutes. While both printers will require label rolls to be changed, thermal transfer labels and ribbons rarely run out at the same time, causing multiple stoppages in productivity vs 1 stoppage for DT.

How Direct Thermal Printng Works - a simple explanation

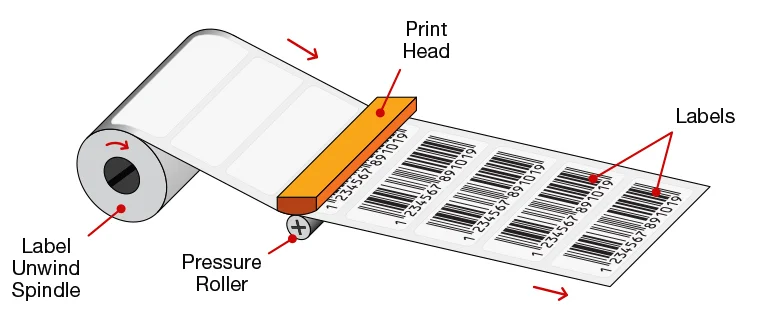

Direct thermal printing produces high-quality barcode labels for numerous applications. Instead of using a ribbon this method uses heated print head to create a chemical reaction within the label itself. This reaction creates the printed scannable image. The only media that passes through the printer is the printable adhesive label paper. The chemical composition of the label paper and the thermal print head is all what is required. Yes, that simple and efficient.

Printer head life can become an issue. Thermal transfer print head life can be significantly longer than direct thermal transfer print head life. The reason for this is that the thermal transfer ribbon acts as a protective barrier against the label surface protecting it from scratches and contaminates. Label surfaces while appearing smooth actually contain imperfections and rough patches which can shorten print head life. One way to reduce wear and tear on print heads is to use a premium topcoated direct thermal label material. The surface has a special coating that makes the material smoother and also helps to protect against smudging of the labels, making topcoated the best choice for materials that go on conveyors and may do a lot of rubbing and bumping into walls, boxes , etc. Better quality bar codes can result in less rejections of bar codes which in some cases may reduce “rejection” fines applied by some of the larger retailers in the US.

Sizes And Adhesives:

All the most commonly used sizes are available in direct thermal materials with 1" core and 3" core rolls, as well as fanfold stacks. The most popular sizes are 4 x 6" and 4 x 2" either on a 3/4", 1", 3" Core or fanfold. Direct thermal materials come with a standard permanent acrylic adhesive. But, in some situations/environments, stronger aggresive or all temp adhesives are required: for recycled corrugated boxes, freezer applications.

Waste:

Another benefit of using direct thermal is that there is less waste. Direct thermal ribbons are poly based, and contribute to the use of fossil fuels and landfill waste. With no ribbons, direct thermal labels create far less waste.

Things To Consider When Choosing To Print Direct Thermal:

- If you need the print to last 6 months or less

- Is more cost effective and will increase productivity

- If you only need to print black and white

- Not good for demanding applications and contact with elements